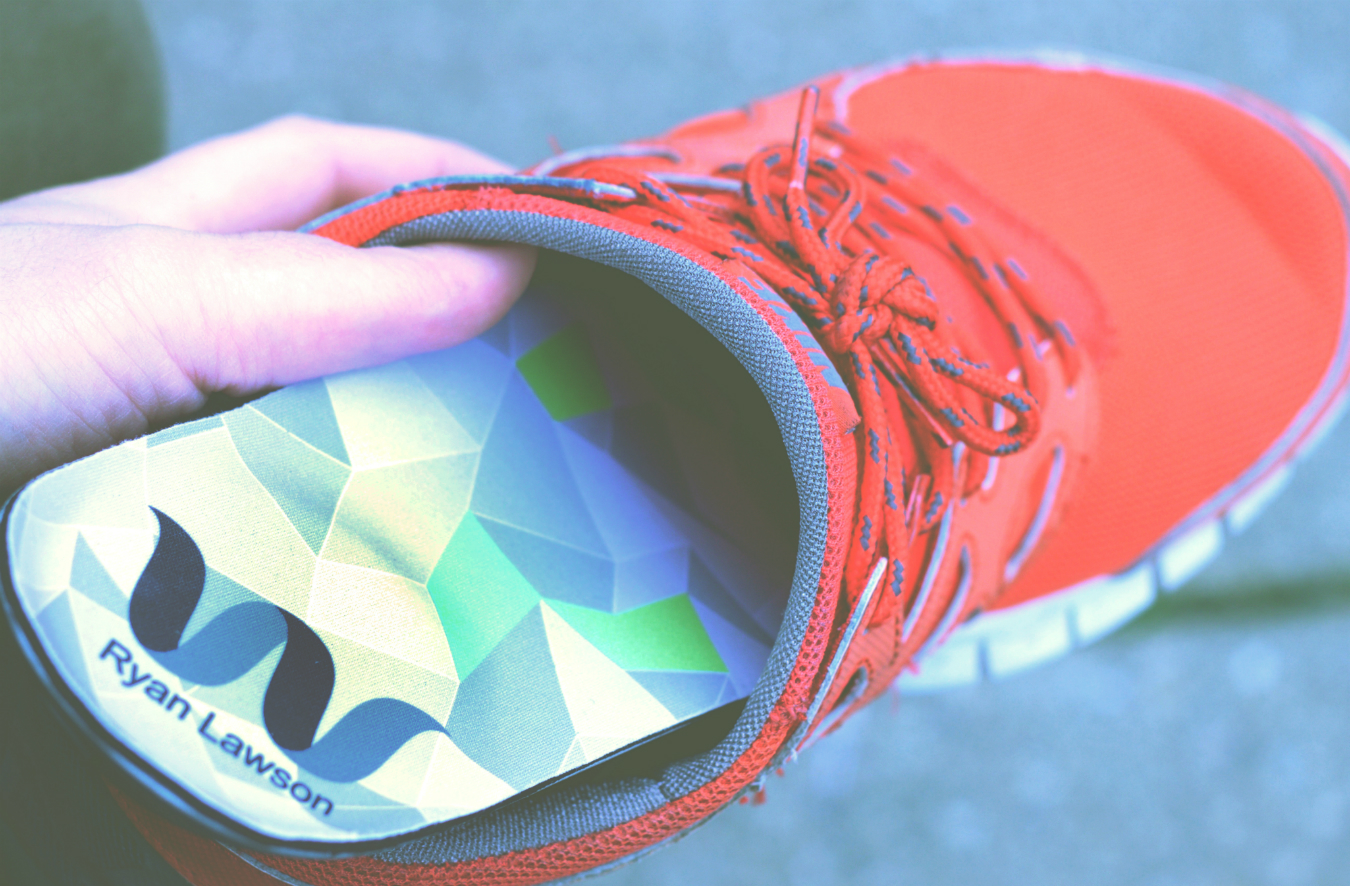

When Shamil Hargovan and Louis-Victor Jadavji decided to build a company from the ground up, they stopped at the feet. Wiivv is a Vancouver-based startup catering to the market of newly dubbed “industrial athletes”—working professionals who spend all day on their feet—by making 3D printed, custom insoles designed to alleviate pain and pressure. But the real magic is the company’s ability to take 2D images from a smartphone and transform them into 3D printable files that they can manufacture at scale. “The process for custom insoles takes around five minutes, and we are able to plot over 200 points on your feet to create a made-to-fit product with only one photo of each foot,” says CEO and co-founder Hargovan. “We are pushing the boundaries of traditional manufacturing and ushering in the age of mass customization.”

Hargovan and his team have zeroed in on a lucrative product: shoes. The problem is that many footwear designs have insufficient built-in support. Nurses, for example, can take nearly 8,000 steps during an average eight-hour workday, with restaurant servers averaging 10,000 in a six-hour shift alone. Needless to say, proper support is crucial. “We like to say that shoes made for everyone fit no one,” Hargovan says. That is because wholesale shoes are made in very binary sizes and are thus not adequately supportive for the individual. Every foot—even comparing a person’s left and right—is completely different, Hargovan adds. When your feet hurt, everything hurts, and that pain is exactly what Wiivv is striving to eliminate. “Our vision here is to add 10 active years to people’s lives so they are able to do what they love, longer,” says Hargovan. “We are literally supporting every step they take, and helping them to keep going is our inspiration every day.”

It’s that do-good mindset combined with their approach to widespread customization through bionic 3D printing that recently landed the duo on Forbes’s esteemed 30 Under 30 list in manufacturing. Now, the company is set on creating made-to-fit gear for other areas of the body using the same technology.

When asked if 3D custom printing is the new era of marketing, Hargovan seems nothing but certain that it is. “We want what we want, when we want it, and we expect it to be made our way in virtually every area of our lives today,” he says. “Consumer goods are lagging behind in this area, largely due to the constraints of mass manufacturing.” Printing in 3D using information taken from a smartphone has the potential to revolutionize the merchandising experience by making custom products accessible and easy to order. Hargovan and Jadavji, along with their growing 20-person team, want to lead the way, and they are doing so by putting one foot—comfortably—in front of the other.

Stay up-to-date. Read more technology stories here.