For a man bound and determined to change the world, Klaus Berger is a pretty humble guy. Sure, you can see the confidence, a certain spark in his eye, a hard-to-describe energy in his smile. But there’s modesty there, too: an understanding that the first and most critical ingredient of success is patience.

This all makes him the perfect man for his current job as vice-president of Mercedes-Benz’s fuel cell division. Together with the Automotive Fuel Cell Cooperation, a joint-venture private company owned by Daimler AG, Ford Motor Company, and Ballard Power Systems (which focuses on industrial applications including buses, forklifts, and generators), Berger’s facility is a key part of Burnaby’s “fuel-cell cluster” located just south of Marine Drive. Here, a dedicated group of scientists, engineers, industrial designers, and technicians are working hard to replace one of the signature technology of modern civilization: the internal combustion engine.

As dreams go, it is not a new one. The basic idea of using a chemical reaction to create electricity dates back to 1839, when physicist William Grove produced crude fuel cells using sulphuric acid. NASA used them extensively in the 1960s and 1970s in its space program. Closer to home, Ballard Power Systems proved almost 20 years ago that hydrogen, the most abundant substance in the universe, could in fact be used to get from point A to point B. But while Ballard was able to build a hydrogen powertrain, it was unable to bring it to market. And that’s where Berger comes in.

“Those activities were mostly based on research: make it happen, and show in principle that it works,” Berger says in his thick German accent. “Now, we are in the second or third phase of this technology, and that means we want to commercialize it.”

As he explains, this means shifting the focus away from pure R&D and toward commercializing the technology itself, so the hydrogen fuel cell can reliably deliver the same comfort, convenience, driving pleasure as a gasoline engine, at roughly the same cost. “We have to develop and modify that existing technology and bring it forward so that the same customer can buy a hydrogen-powered car—so that it doesn’t make any difference for them.”

“It’s a living factory. What you would have seen two months ago looks different than what you see today.”

In this respect, his task is not so much to dream as it is to refine, perfect, and make real. By creating ever more efficient processes by which a fuel cell comes to life, Berger and his team are the critical link between the drawing board and the factory floor, between science fiction and economic reality.

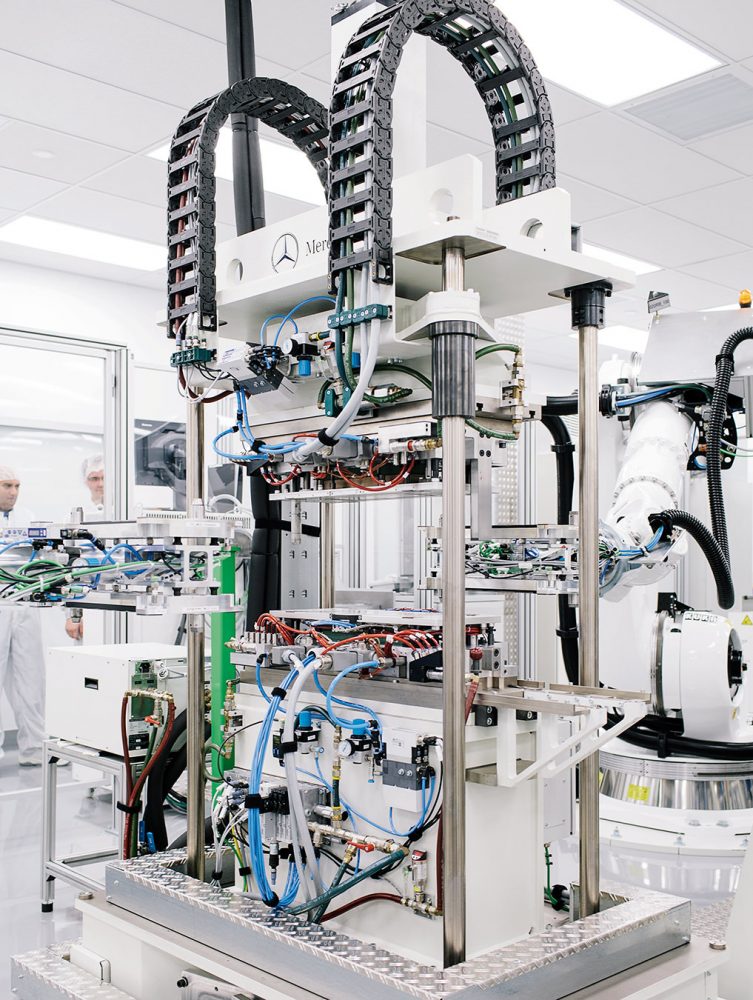

Of course, such efforts require deep pockets. Mercedes spent over $40-million renovating, expanding, and stocking the Burnaby facility with cutting-edge production technology, including the construction of a multi-million dollar “clean room” where the actual cells are put together. As Berger explains, his job is not only to build a better fuel cell, but to build a better assembly line that builds a better fuel cell. “It’s a living factory,” he says. “What you would have seen two months ago looks different than what you see today.”

Within the clean room, production is largely automated. Imposing 2.5-metre-tall robot arms do the precision work while a dozen or so skilled technicians monitor systems, perform quality control, and make various adjustments. Most of what fills the room was purpose-built for the job. “For some key technologies that are not available on the market or not mature enough, we build up and develop our own machines,” Berger says. “This approach is faster and enables us to have a real thorough understanding of the technology.”

Berger holds up a cell—a collection of wafer-thin polymer membranes where hydrogen and air come together to make electricity. The “stack”—the series of up to 500 individual cells that collectively provide power to the wheels—is about the size of an overstuffed laptop bag. On a typical day, Berger’s team will build between five and 10. The goal, however, is not to meet a production quota, but to constantly improve: at each step, technicians try to evaluate minute changes that could lead to making the stacks faster, with fewer resources, using less energy in less time.

Once produced, each stack is put through its paces to measure the health of each cell. Ideally, hydrogen and oxygen will flow through the stack without blockages or leaks (consider the fate of the Hindenburg), and the load measured will meet the design’s 80 kilowatt specification, approximately the amount needed to power a mid-sized sedan. When it doesn’t, Berger’s team tries to find out why: was it a manufacturing problem? A design problem? A materials problem? Something else? Every question usually leads to two or three more.

Each component of the stack is labelled with a specific code, so defects can be easily identified and tracked back through the production floor. For now, quality control must be completed by human beings—at least until Berger can tell the robots what to look for. “We have to think about how we can ‘algorithm’ it,” he says, “so it can be recognized automatically.”

Looking about the factory, it’s hard not to be impressed at the scale of Berger’s operation, to say nothing of the dedication of his team. They have made considerable progress so far: in the past four years, production costs for hydrogen fuel cells have dropped by 50 per cent. Even so, Berger admits that his team needs to reduce production costs by another 80 per cent to make a hydrogen-powered car commercially viable.

“We will get the technology together. For me, the question is how long, how fast, how efficient can we be on that pathway. That is the major issue for me.”

And when, exactly, will that happen? Berger’s estimate: three years, give or take a couple of months. “The main challenge is the time that’s needed to combine the needed brains together and to make them work,” he says. “We will get the technology together. For me, the question is how long, how fast, how efficient can we be on that pathway. That is the major issue for me.”

In the meantime, we will reap the rewards. British Columbia is fast becoming a hub for clean-tech start-ups, a place renowned for bringing technology and environmental ideals together. Where Mercedes has come, specialist suppliers, research facilities, and a considerable pool of engineering talent have followed. Indeed, this is one of the reasons Berger decided to set up shop here rather than take the work home to Stuttgart. “Without having that infrastructure here … we would not have been able to show up in such a short time,” he explains.

Watching Berger walk about his factory in his nondescript white lab coat, pointing to the various machines, explaining the challenges that remain, one can’t help but reconsider the nature of technology and change. Progress is usually considered the child of the eureka moment—that instant of sublime creativity when the big idea springs forth from the mind of the creator. This too is a dream. In truth, the garbage cans of the world are full of big ideas that never made it off the notepad. Those that do invariably owe a debt of gratitude to people like Berger.

Not that Berger is having any of that. “I am proud of it,” he says in a quiet voice, nodding his head and looking over at his work. Then the humility takes over. “I’m part of the team. I give some directions. I’m responsible for getting rid of some major hurdles. And that is my job.” Even so, it’s hard not to notice that spark in his eye.